Description

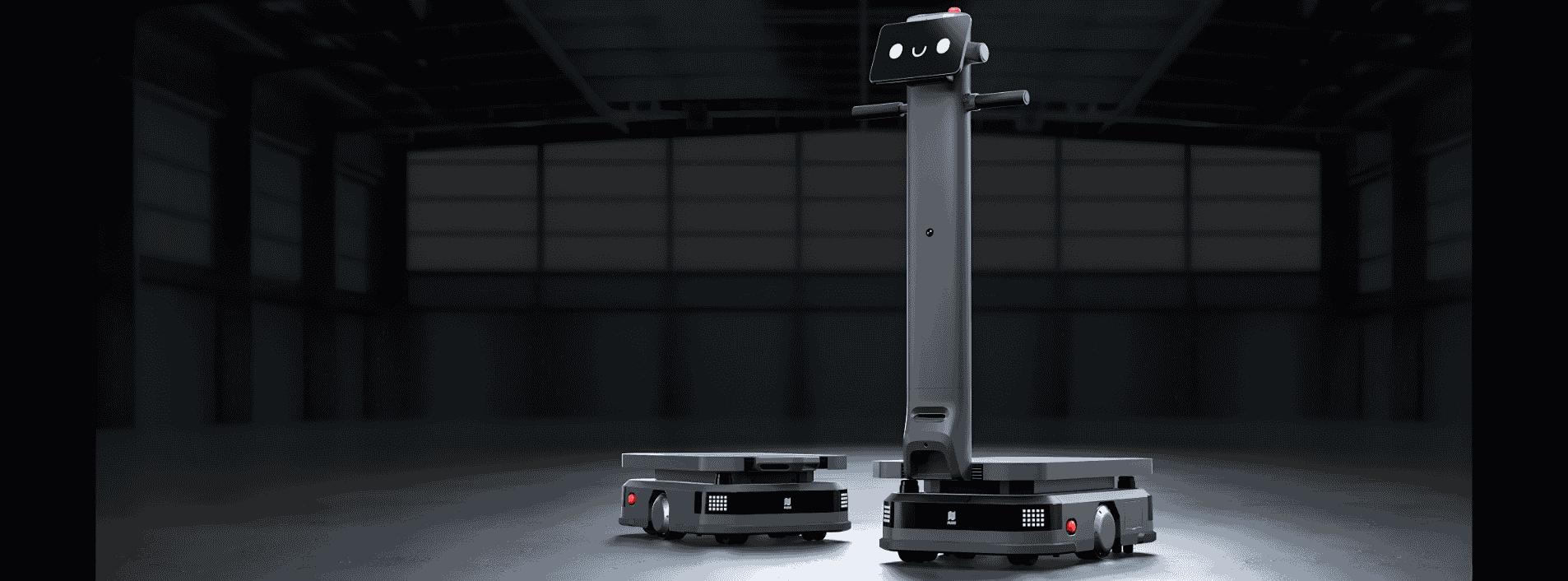

PUDU T600 Underride Flexible & Efficient Industrial Delivery Platform

| Parameter | Detail |

|---|---|

| Model / Type | PUDU T600 Underride |

| Payload Capacity | Up to 600 kg |

| Dimensions (L × W × H) | 845 × 500 × 255 mm |

| Robot Weight | ~ 94 kg |

| Cruise / Operating Speed | 0.2 – 1.2 m/s (site & load dependent) |

| Battery / Runtime | Up to ~12 h (no load) |

| Charging Time | ≈ 2 h (0 → 90%) fast charge |

| Minimum Aisle / Path Clearance (Recommended) | ≥ 65 cm (aisle width) |

| Navigation / Localization | LiDAR SLAM + VSLAM (dynamic path planning, obstacle detection) |

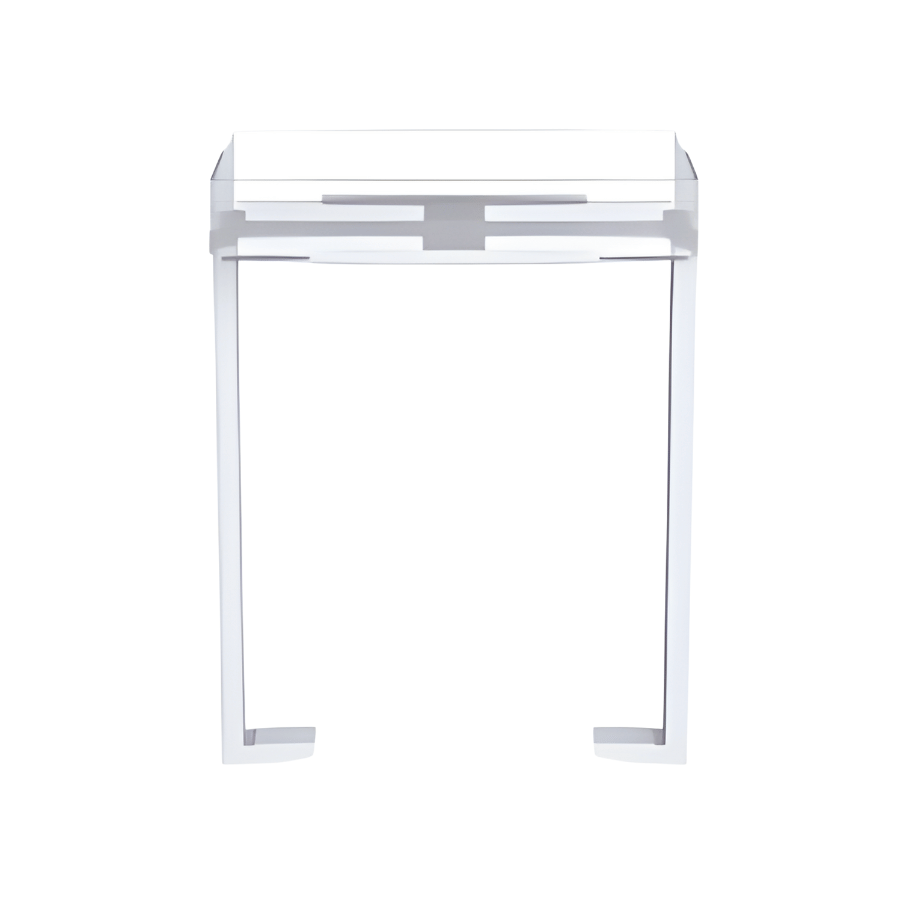

| Load Handling / Rack Capability | Can slip under racks/shelves, autonomously lift & transport them — enabling shelf-to-shelf or shelf-to-line operations. |

| Environment / Operating Conditions | Recommended for warehouse/factory floors; designed for standard industrial environments. |

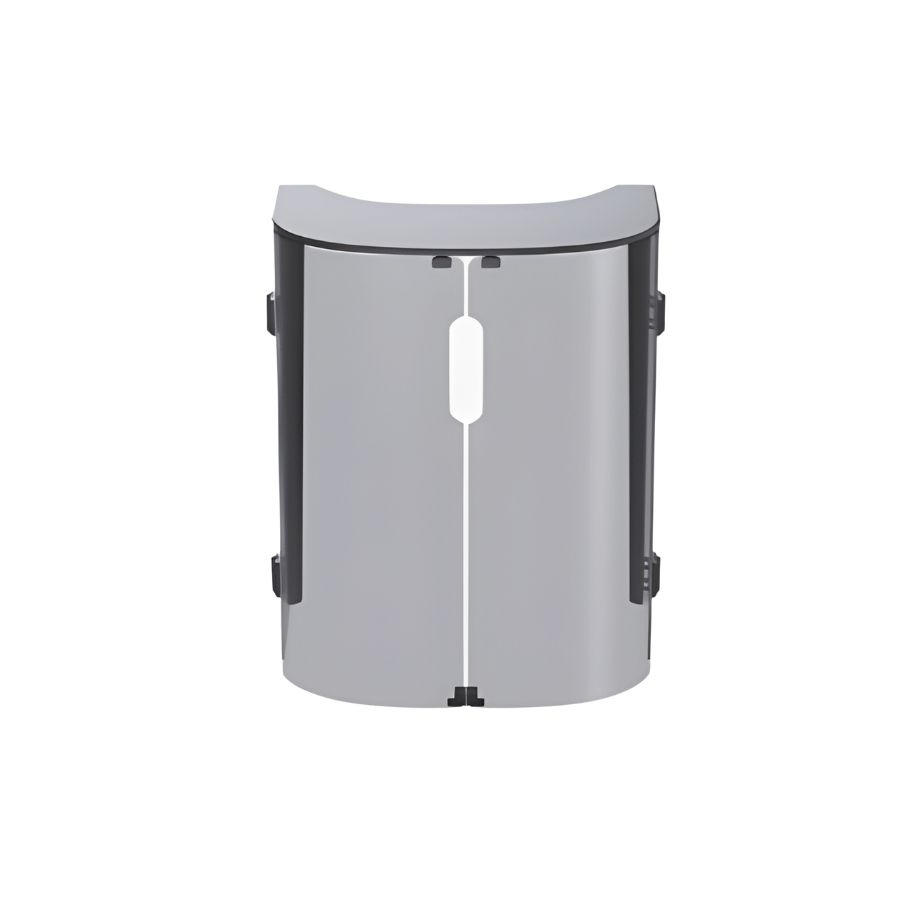

The PUDU T600 Underride is a compact, chassis-style industrial delivery robot designed to transform automated material handling. Its ultra-low-profile structure allows it to glide smoothly beneath rack units and lift them autonomously, eliminating the need for manual intervention.

With its intelligent underride capability, the robot lifts loads from the center, ensuring stable handling while requiring only minimal aisle clearance. This agile design helps facilities move goods more efficiently, especially in tight or complex warehouse layouts. The T600 Underride navigates with precision, boosts operational flexibility, and supports continuous, high-performance logistics automation.

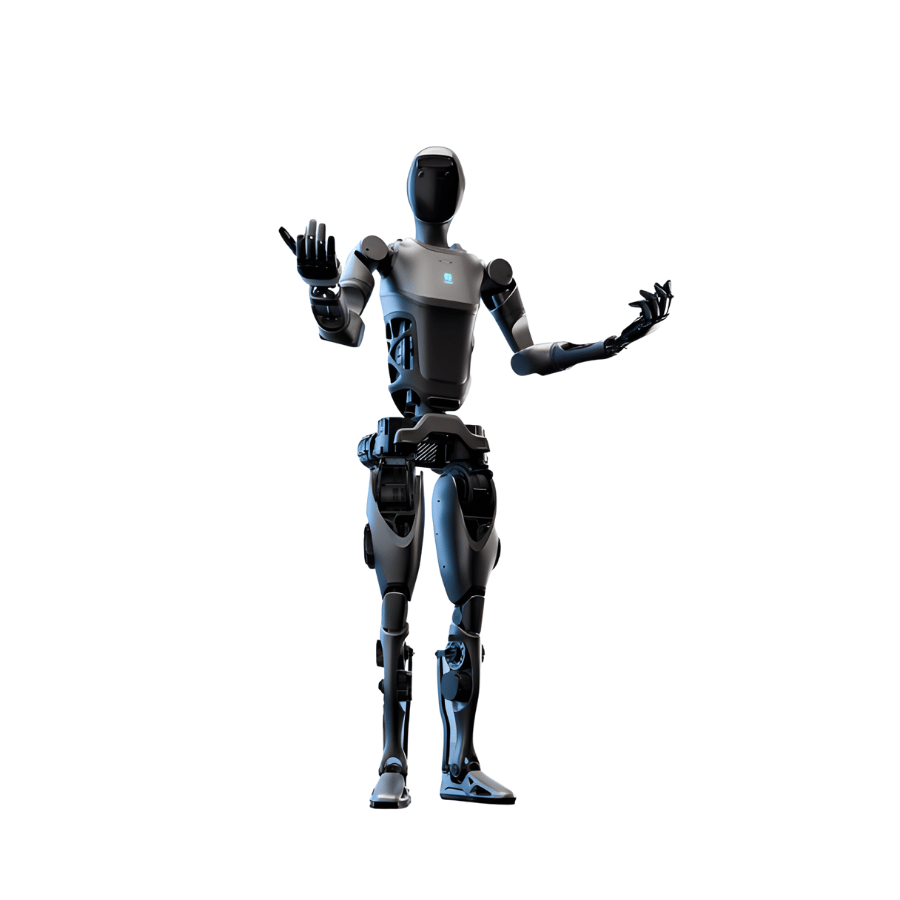

PUDU T600 Industrial Robot

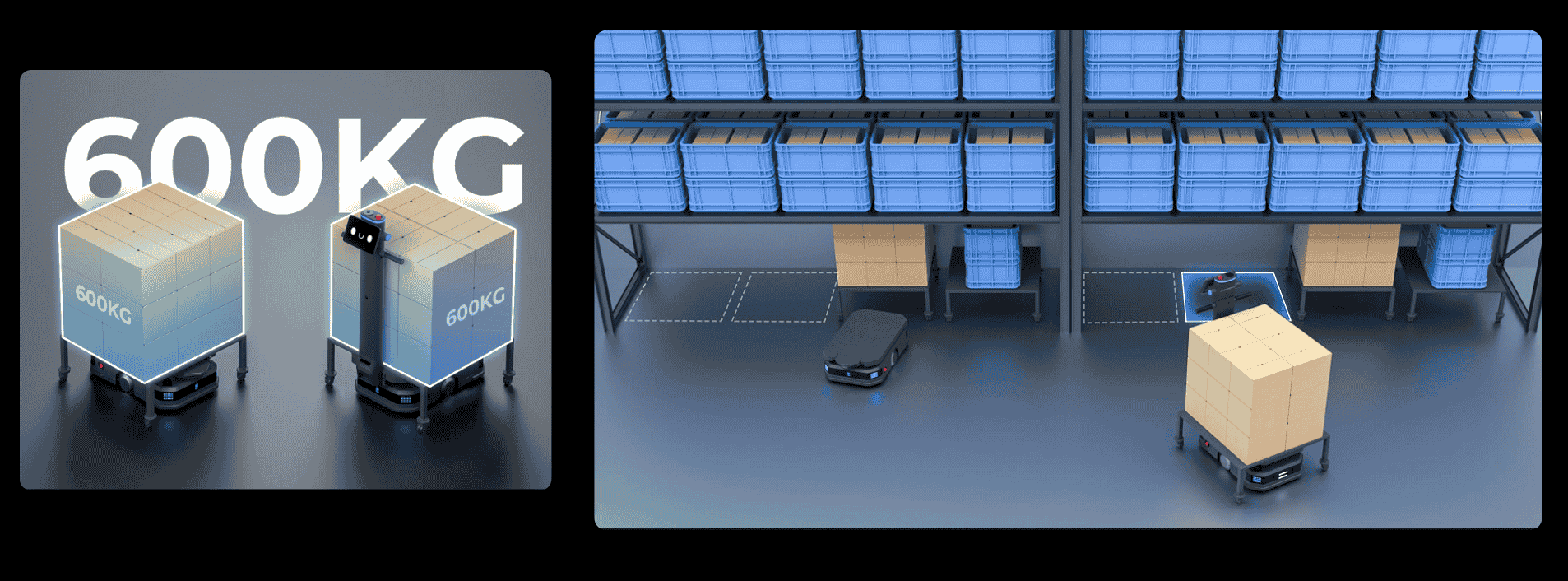

600 kg Heavy-Payload Capacity

The T600 series delivers true heavy-duty performance with its impressive 600 kg payload capacity. It handles large, bulky loads with ease, allowing each trip to move significantly more material. As a result, your operations reduce delivery frequency, streamline workflow, and achieve higher efficiency with every run.

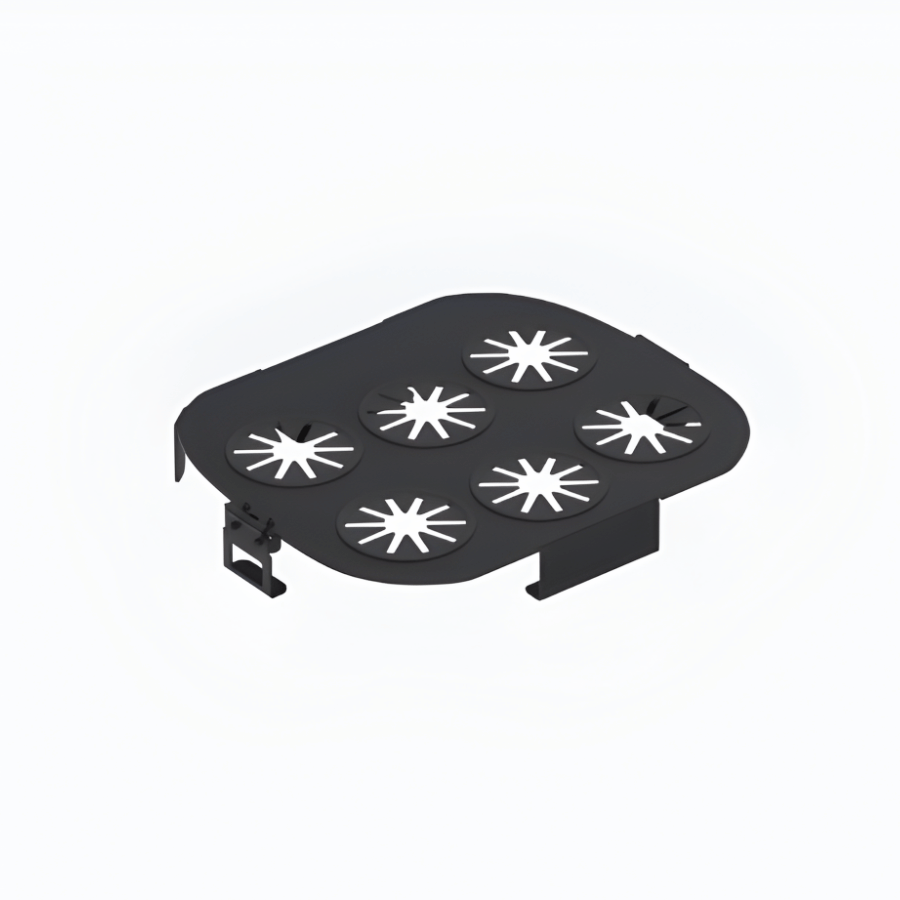

Intelligent Rack Group Recognition

Equipped with advanced navigation and perception technology, the T600 series accurately recognizes rack groups and identifies designated storage points. It autonomously executes pick-and-place tasks, enabling a fully unmanned material-handling process. This smart automation ensures faster, more reliable, and highly consistent warehouse operations.

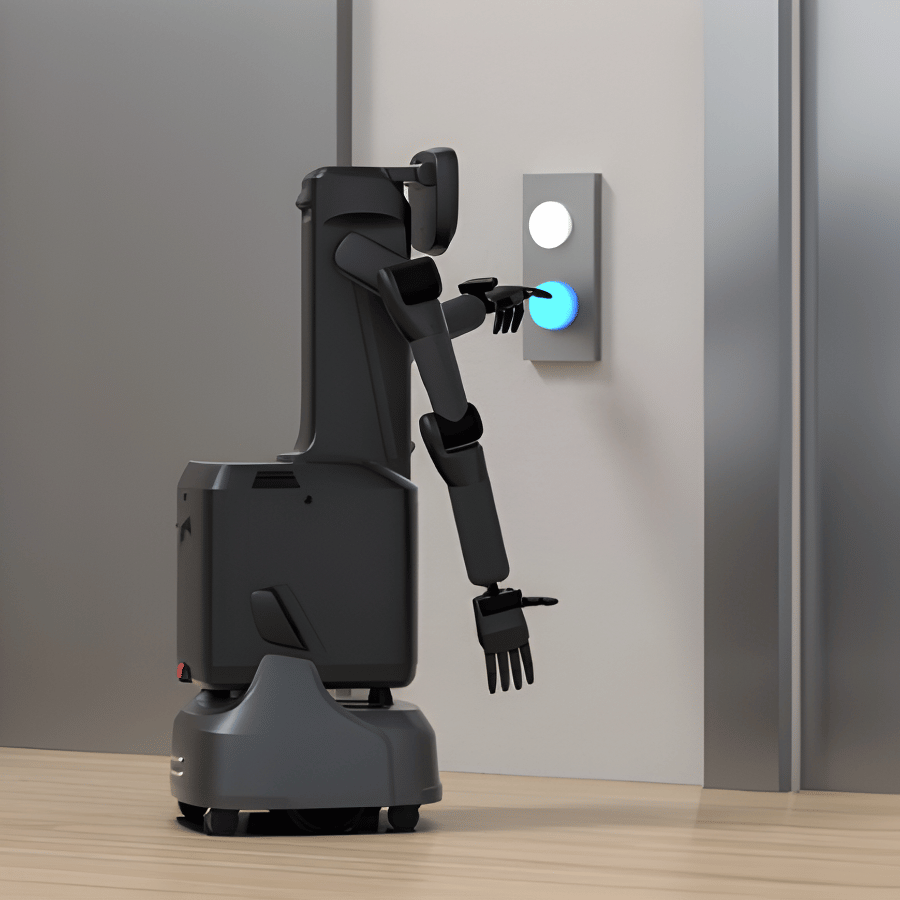

Idle Elevator Priority Scheduling

The T600 series uses intelligent scheduling to always call the idle elevator first. In facilities with multiple elevators, the system continuously monitors elevator status and automatically prioritizes the available ones. This reduces congestion during peak hours, prevents resource bottlenecks, and dramatically boosts cross-floor delivery efficiency.

Smart Narrow-Aisle Traffic Management

The system evaluates aisle width and the robot’s real-time load dimensions to decide whether to use single-lane or dual-lane movement. It dynamically adjusts traffic flow to maximize space usage and keep operations smooth, enabling efficient multi-robot coordination even in tight, narrow environments.

Flexible & Fast Deployment

The T600 series adapts quickly to layout changes without requiring lengthy reconfiguration or major facility adjustments. This flexibility allows operations to scale or restructure rapidly while keeping downtime to a minimum.

VDA5050 Protocol Compatibility

The T600 series seamlessly supports the VDA5050 standard communication protocol, allowing it to work effortlessly with other compliant robots and management systems. This eliminates the need for custom development or complicated integrations, enabling fast deployment and creating a unified, scalable, and highly efficient logistics network.

Secure On-Premises Deployment

The system offers full support for on-premises deployment, giving businesses complete control over their data and operational environment. This setup enhances security, stability, and compliance for mission-critical automation.

Ground Projection Safety Indicator

A clear linear light projection is displayed in front of the T600, visually marking its travel path. This ground-level warning signal creates a safer, more predictable workspace for human-robot collaboration.

Advanced Dynamic Obstacle Avoidance

The T600 series automatically detects low-lying obstacles and adjusts its route in real time. This intelligent navigation ensures smooth, safe movement and minimizes operational interruptions.

Intelligent Disaster Avoidance System

The T600 series includes a dedicated disaster avoidance module that responds instantly to emergency signals such as fire alarms or earthquake alerts. It autonomously navigates to a safe zone or stops and parks securely based on real-time conditions. This smart safety logic enhances protection for both personnel and equipment.

Effortless Handle Assist Switch

The T600 comes with an ergonomic handle assist switch that makes operation incredibly simple. With just a press of the switch, you can guide and control the T600 smoothly—even when moving heavy loads—reducing strain and boosting productivity.

Reliable 24/7 Performance

Designed for continuous operation, the T600 series delivers up to 12 hours of battery life and recharges in as little as 2 hours. With automatic docking for recharging and quick battery swap options, it keeps working non-stop to meet demanding, round-the-clock workflows.

There are no reviews yet.