Description

Product Specifications

| Category | Specification |

|---|---|

| Product Name | Agibot A2-W Flexible Manufacturing Robot |

| Robot Type | Mobile Dual-Arm Industrial Robot |

| Mobility | Wheeled autonomous mobile base |

| Navigation | Autonomous indoor navigation |

| Arms | Dual articulated robotic arms |

| Degrees of Freedom | 30+ DOF |

| End Effectors | Industrial grippers (customizable) |

| Payload Capacity | Approx. 5–10 kg (per arm) |

| Vision System | Stereo vision + depth cameras |

| Sensors | Vision, proximity, force, IMU |

| AI Capabilities | Task planning, perception, decision-making |

| Obstacle Avoidance | Real-time AI-based avoidance |

| Control System | AI robotic control platform |

| Connectivity | Wi-Fi, Ethernet |

| Power Source | Rechargeable lithium battery |

| Operating Time | Approx. 6–8 hours (usage dependent) |

| Charging | Docking / direct charging |

| Materials | Industrial-grade aluminum & composites |

| Operating Environment | Indoor industrial environments |

| Applications | Assembly, logistics, material handling |

| Integration | Compatible with smart factory systems |

| Customization | Hardware & software configurable |

Experts in Flexible Manufacturing with End-to-End Automation Solutions

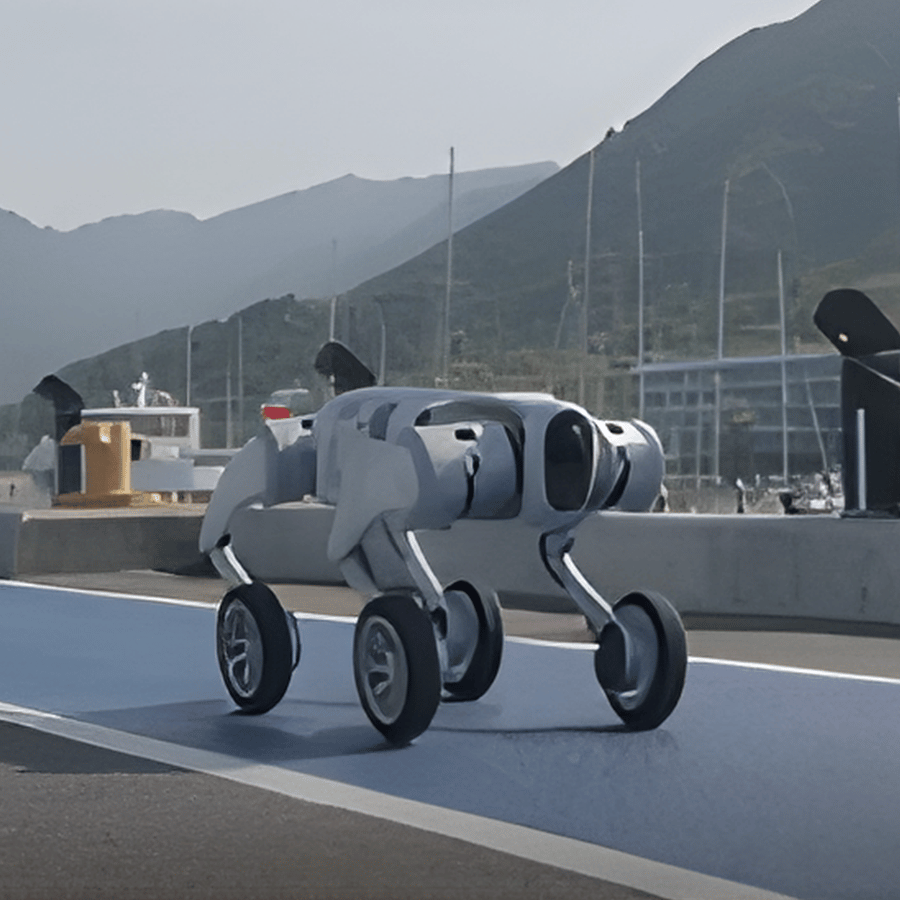

AGIBOT A2-W is a versatile, wheeled general-purpose robot engineered for flexible manufacturing environments. It efficiently performs tasks such as grasping, placing, transporting, and terminal plugging, making it well suited for modern industrial automation. Powered by self-developed embodied intelligence algorithms, AGIBOT A2-W supports secondary development through open interfaces and tools, allowing seamless customization and integration.

As it operates, AGIBOT A2-W continuously improves through data accumulation, becoming smarter and more efficient over time. Its bionic dual-arm design, combined with high-precision force control, multiple depth and vision sensors, and a four-wheel-drive system, ensures stable, flexible, and safe operation in complex industrial environments. The robot supports out-of-the-box deployment and hot-swappable battery replacement, minimizing downtime and maximizing productivity.

AGIBOT A2-W is ideal for applications such as loading and unloading, terminal connections, and logistics transportation, making it a powerful solution for boosting production line automation and achieving truly flexible manufacturing.

Dual-Arm Collaboration with Extended Full-Range Reach

The system features bionic dual arms with seven degrees of freedom, enabling both synchronized and independent operation for greater flexibility. This design allows smooth mid-air object transfer and precise hand-offs, making it easy to handle complex workpieces and maintain accurate positioning in specialized tasks.

A four-wheel-drive base with zero turning radius and crab-walking capability ensures exceptional mobility in confined spaces. The adjustable waist can lift and tilt, providing 22 degrees of freedom and allowing the robot to fully cover the human working range. Together, these capabilities enable efficient, safe, and highly adaptable operation across dynamic industrial environments.

Efficient Deployment with Flexible, Intelligent Operation

The system features a fully integrated design that unifies the chassis, robotic arms, and perception system, enabling rapid deployment and commissioning within a single day. This streamlined architecture minimizes setup time and allows businesses to bring automation online quickly.

By leveraging advanced embodied intelligence capabilities such as UniGrasp, Uni6DPose, and UniPlug, combined with 275 TOPS of computing power, the robot delivers millisecond-level real-time object recognition, pose estimation, and intelligent decision-making. This allows it to adapt dynamically to changing tasks and flexible working environments.

In addition, 3D model synthesis training paired with reinforcement learning dramatically shortens adaptation time, enabling the system to learn and handle new objects within hours instead of days, improving efficiency and scalability in modern manufacturing operations.

Continuous Model Evolution with Intelligent Self-Improvement

The system features a modular architecture built around atomic capabilities, enabling over-the-air (OTA) updates that continuously expand and refine the task skill library. With each update and deployment, the robot becomes more capable, adaptable, and efficient.

Through ongoing data collection and training, the embedded intelligence algorithms continuously optimize performance, allowing the system to learn from real-world operation and improve over time. An integrated pipeline for data acquisition, simulation training, and inference deployment streamlines development and accelerates updates, ensuring fast, reliable deployment of new capabilities across evolving application scenarios.

Multi-Modal Perception for Enhanced Safety

The system uses advanced multi-modal perception by combining 360° LiDAR, AI vision sensors, and six-axis force sensors to deliver precise, real-time environmental awareness. This multi-sensor fusion enables millisecond-level detection, intelligent obstacle recognition, and proactive collision avoidance in dynamic environments.

An integrated arm collision detection system, along with 360° real-time environmental sensing and redundant perception and control architecture, ensures safe operation around people, equipment, and infrastructure. This comprehensive safety design protects both personnel and the surrounding workspace, making the system reliable for continuous industrial use.

Sustained Operation with Minimal Maintenance

Designed for long-term reliability, the system supports hot-swappable batteries, allowing energy replenishment within minutes and enabling autonomous charging to reduce manual intervention. This ensures uninterrupted operation and higher productivity in demanding workflows.

Built-in real-time self-diagnostics and self-recovery mechanisms continuously monitor system health, quickly identifying and resolving issues before they cause downtime. These intelligent maintenance features significantly reduce unplanned outages and maintenance costs, ensuring stable, efficient operation over extended periods.

There are no reviews yet.