Description

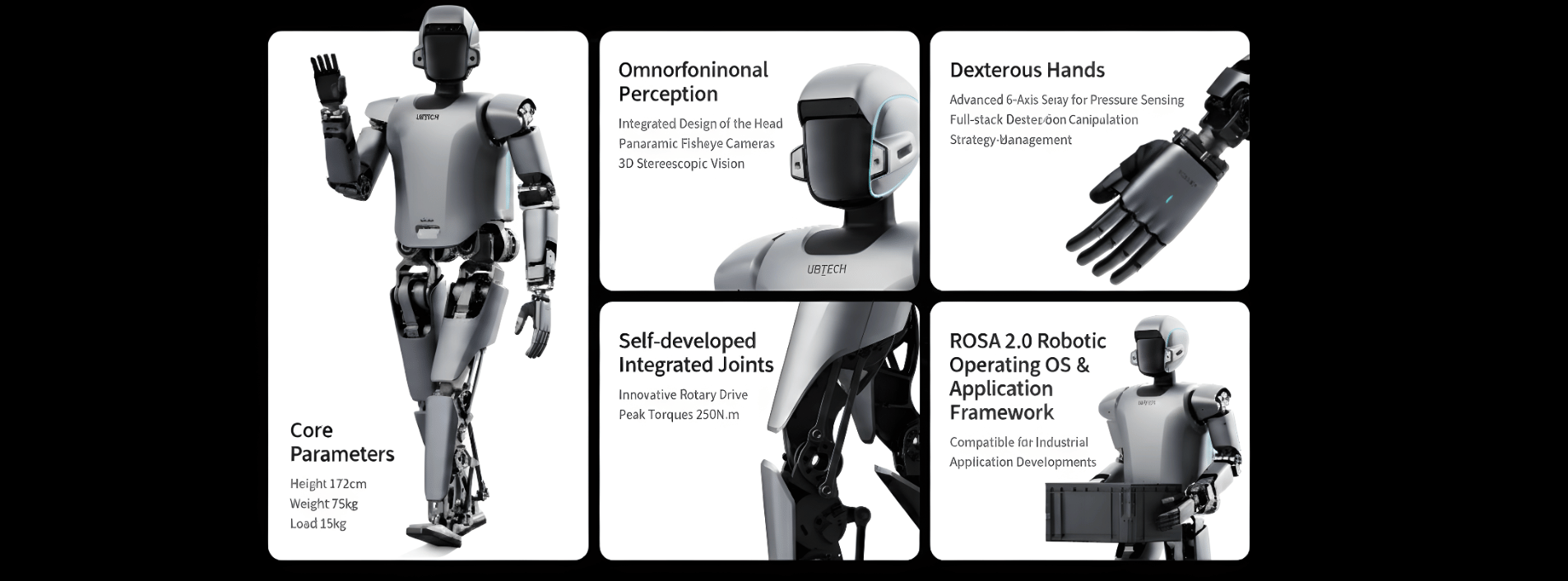

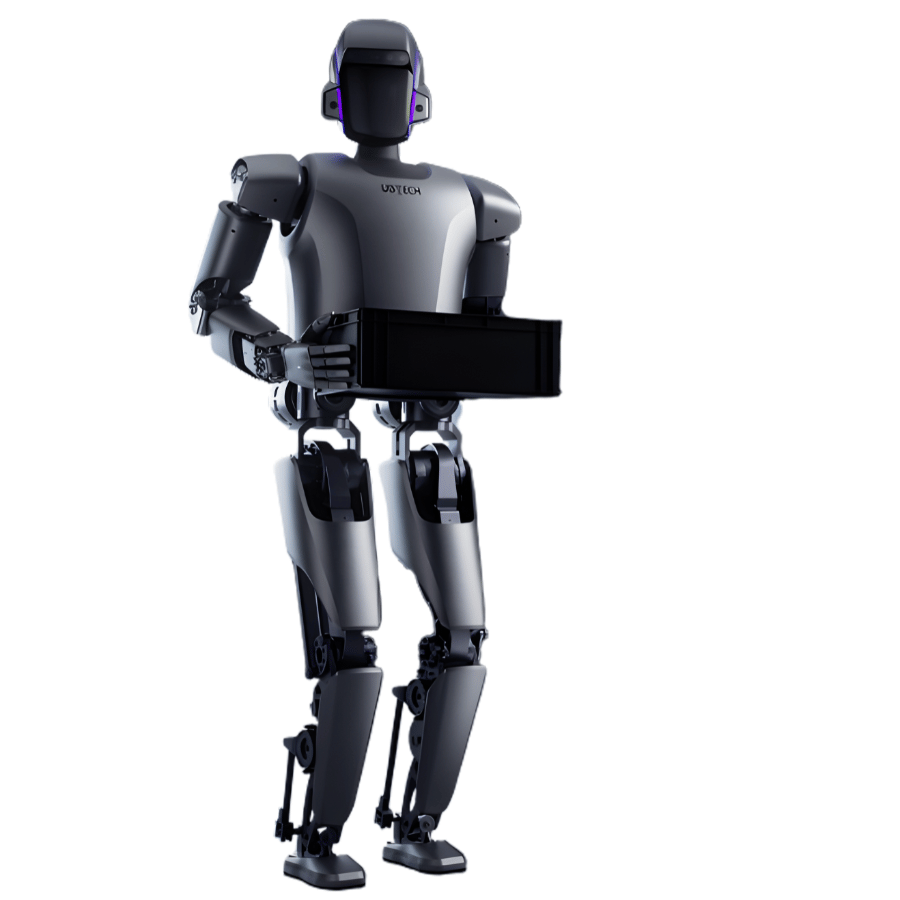

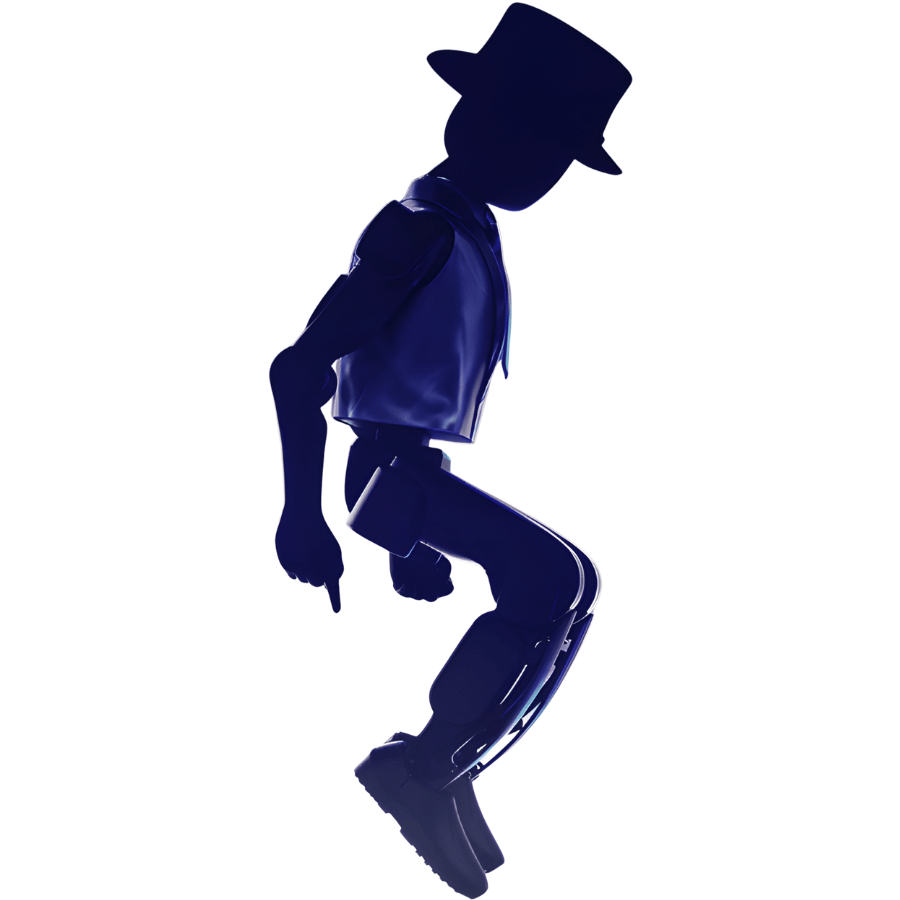

UB Tech Walker S1

| Specification | Details |

|---|---|

| Product Name | UBTECH Walker S1 |

| Type | Industrial Humanoid Robot |

| Manufacturer | UBTECH Robotics |

| Height | ~172 cm |

| Weight | ~76 kg |

| Payload Capacity | Up to 15 kg |

| Degrees of Freedom | 41 DOF |

| Mobility / Speed | Bipedal locomotion (approx. walking speed ~3 km/h) |

| Navigation System | Semantic VSLAM + perception fusion |

| Motion Control | Learning-based whole-body motion control |

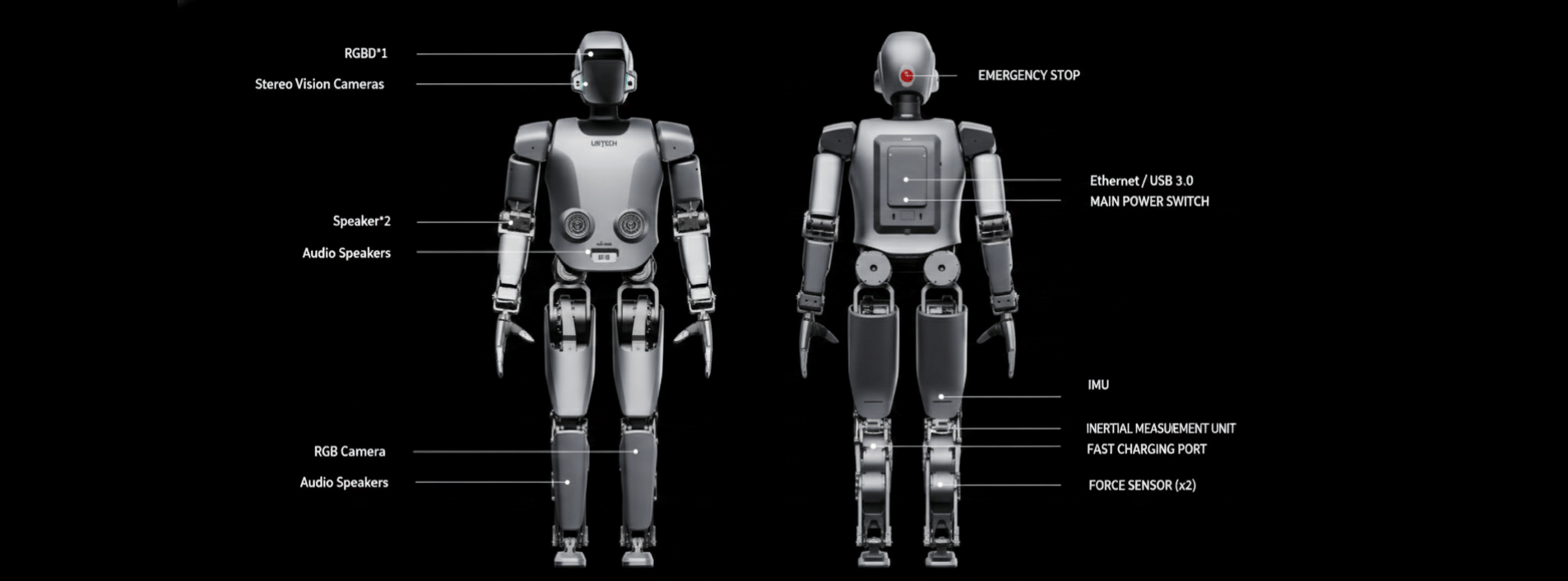

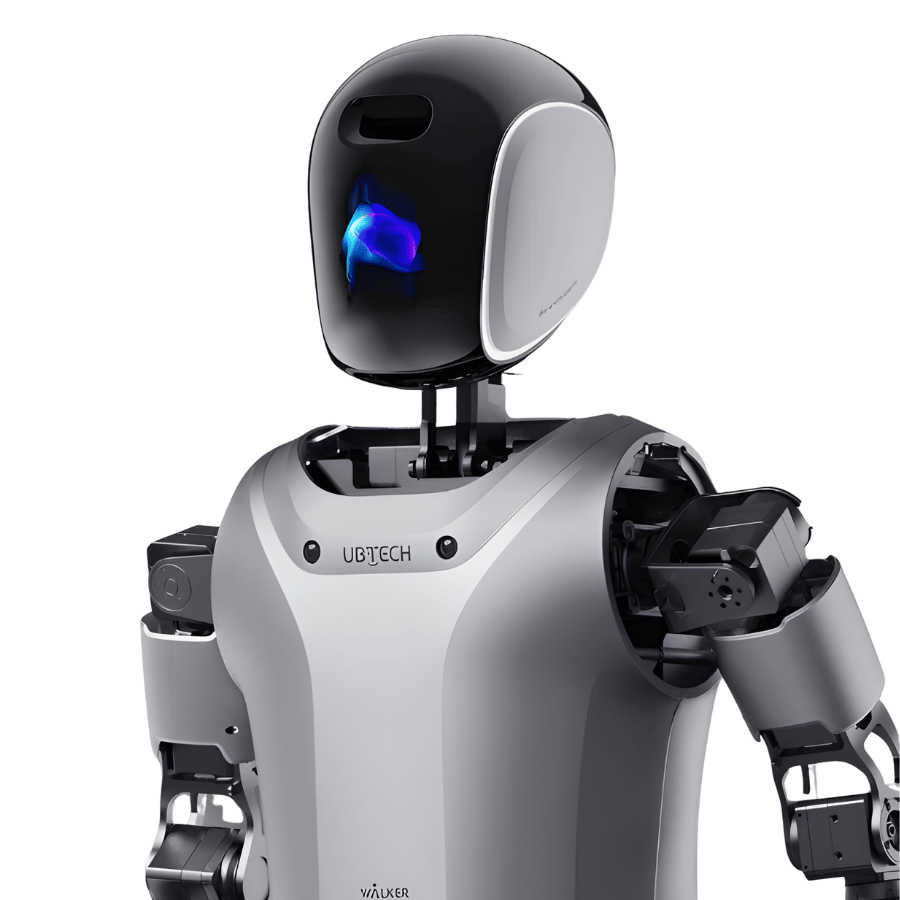

| Perception | Multimodal sensors including cameras and depth systems |

| AI Integration | Large language model for general task planning |

| Battery / Runtime | ~2 hours (varies by load and use case) |

| Operating Environment | Industrial, dynamic, unstructured environments |

| Use Cases | Manufacturing, logistics, assembly, inspection |

| Connectivity | Standard network/sensor interfaces (varies by setup) |

| Control Software | AI-driven embedded framework (ROSA 2.0 / industrial control stack) |

| Industrial Collaboration | Works with AMRs, AGVs, and smart factory systems |

Large Language Model–Powered General Task Planning

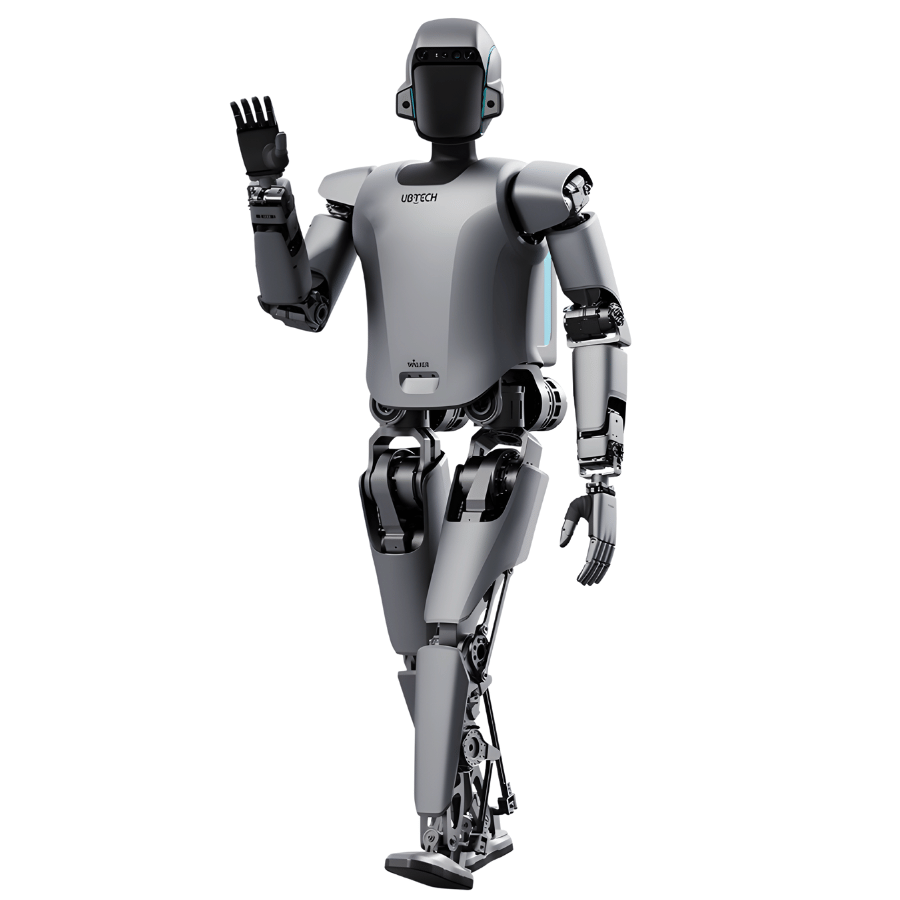

Walker S1 is powered by an advanced large language model that enables intelligent understanding of human intent and precise task planning. This cutting-edge planning technology allows the robot to analyze complex instructions, make informed decisions, and execute tasks efficiently in dynamic environments. With its innovative real-world applications and high level of technical sophistication, Walker S1 stands at the forefront of global humanoid robotics, setting a new benchmark for intelligent industrial automation.

Learning-Based Whole-Body Motion Control for Industrial Humanoid Robots

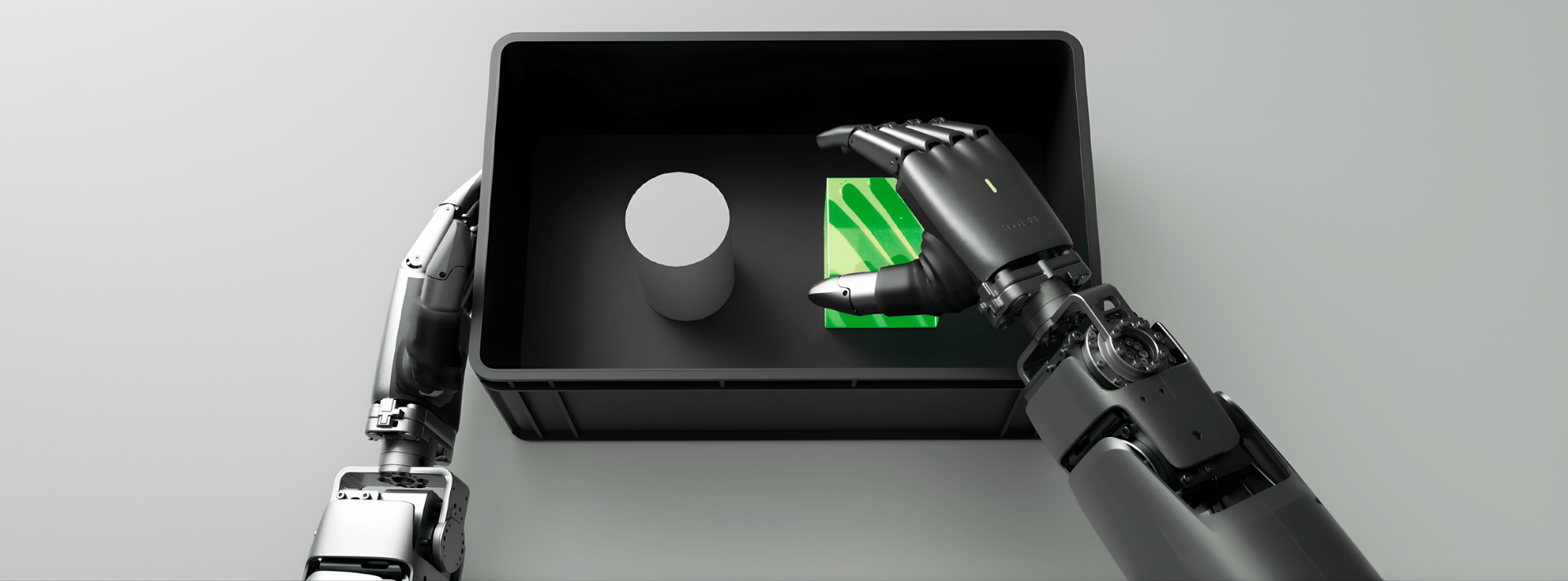

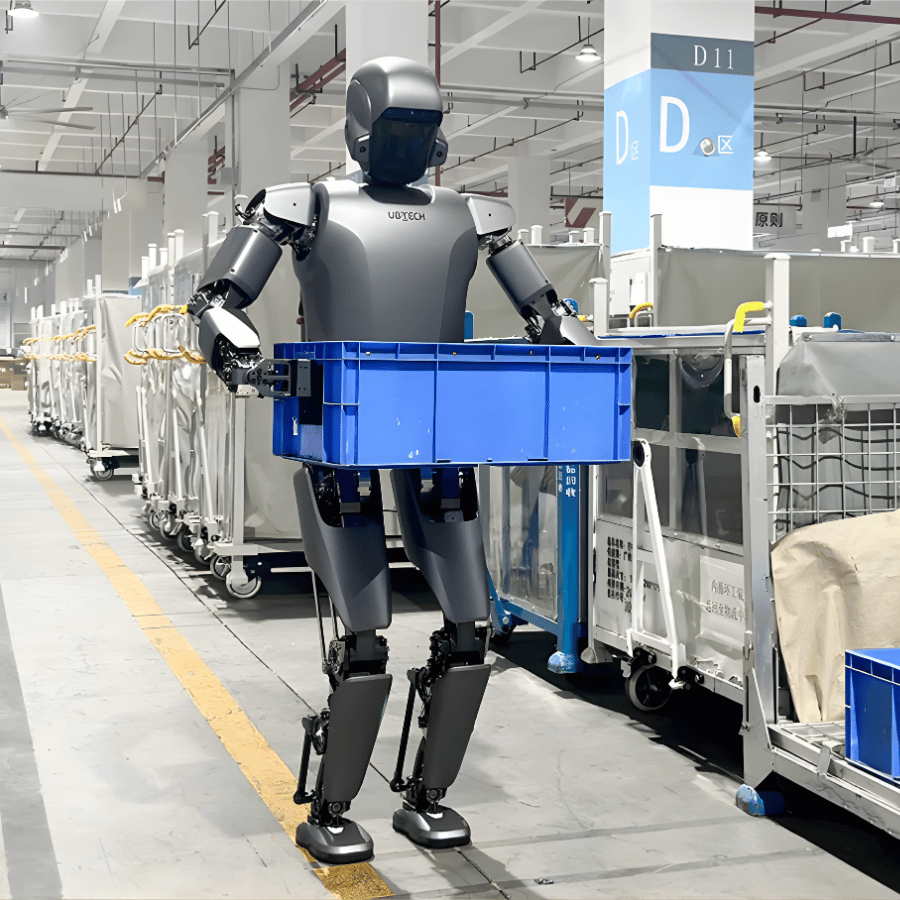

Walker S1 leverages a learning-based whole-body motion control system that seamlessly integrates perception and control into a unified, end-to-end framework. This intelligent motion technology empowers the robot with precise manipulation, stable bipedal walking, and adaptive coordination across its entire body. As a result, Walker S1 delivers reliable performance and flexible execution when handling complex, non-structured tasks in demanding industrial environments, making it a powerful solution for next-generation smart manufacturing and automation.

https://roborises.com/wp-content/uploads/2025/12/UB-Video.mp4

Key Technical Challenges in Industrial Humanoid Robotics

Industrial humanoid robots face visual positioning challenges when operating under changing lighting conditions and complex environments, which can impact perception accuracy and task execution. Motion control algorithms must also adapt in real time to dynamic, high-load scenarios to ensure stability, precision, and safety during demanding operations. Additionally, long-term high-load usage places significant stress on joint systems, making efficient cooling and thermal management critical for maintaining performance, reliability, and operational longevity.

Product Specifications

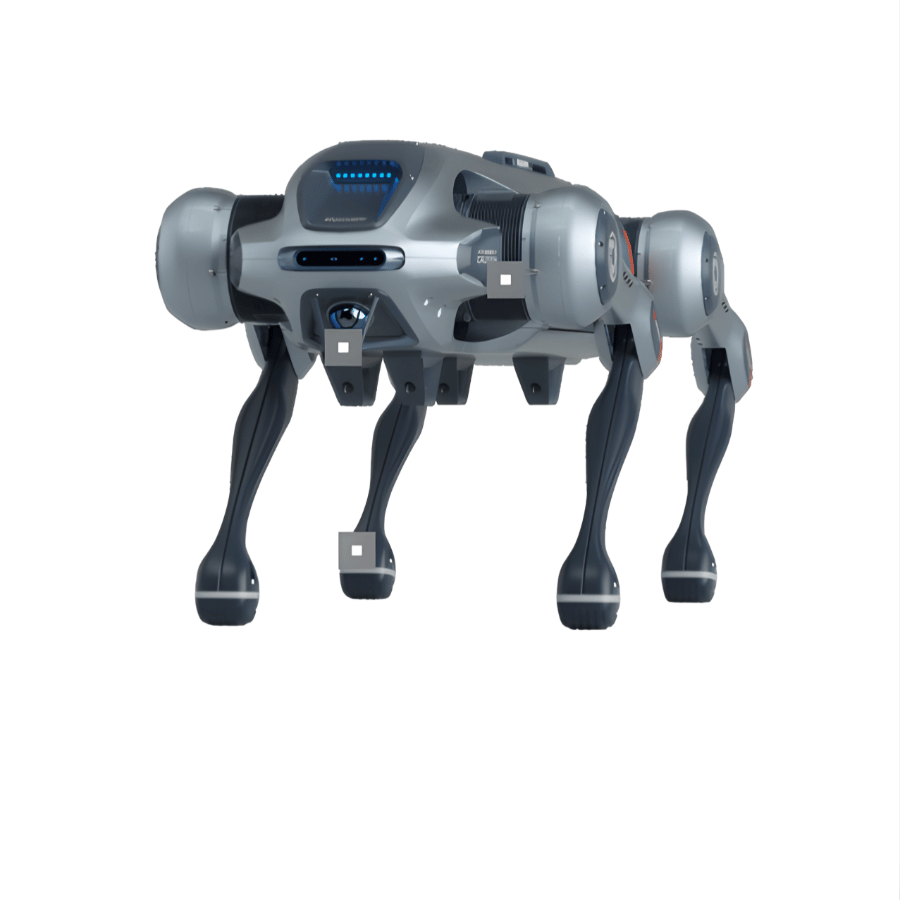

Humanoid Robot Application Solutions for Multi-Task Industrial Environments

Walker S1 delivers advanced humanoid robot solutions for multi-task industrial scenarios, seamlessly integrating into vehicle manufacturing assembly lines to support modern car production. The robot collaborates intelligently with autonomous logistics vehicles, AMRs, and AGVs through smart manufacturing management systems, improving workflow efficiency, operational flexibility, and overall production intelligence in automated factories.

http://roborises.com/wp-content/uploads/2025/12/无人物流解决方案视频_EN.mp4

There are no reviews yet.